Wood Firing Process Described Entry two. November 2025

Loading the kiln is an art in itself. Making sure it is tightly packed, stable, and has proper flow for the flame.

First— I must start with a parallel to parenting.

Caregivers constantly gather information to predict behavior and help soothe our small counterparts. How much did she eat? How long were her naps? Has she been outside? It all factors into how we respond next and it helps us feel in control.

I have found some “kid people” can observe and name a feeling, without any context. When Bev (86) fires a wood kiln, she doesn't watch the thermometers; she listens to the fire and watches the flame.

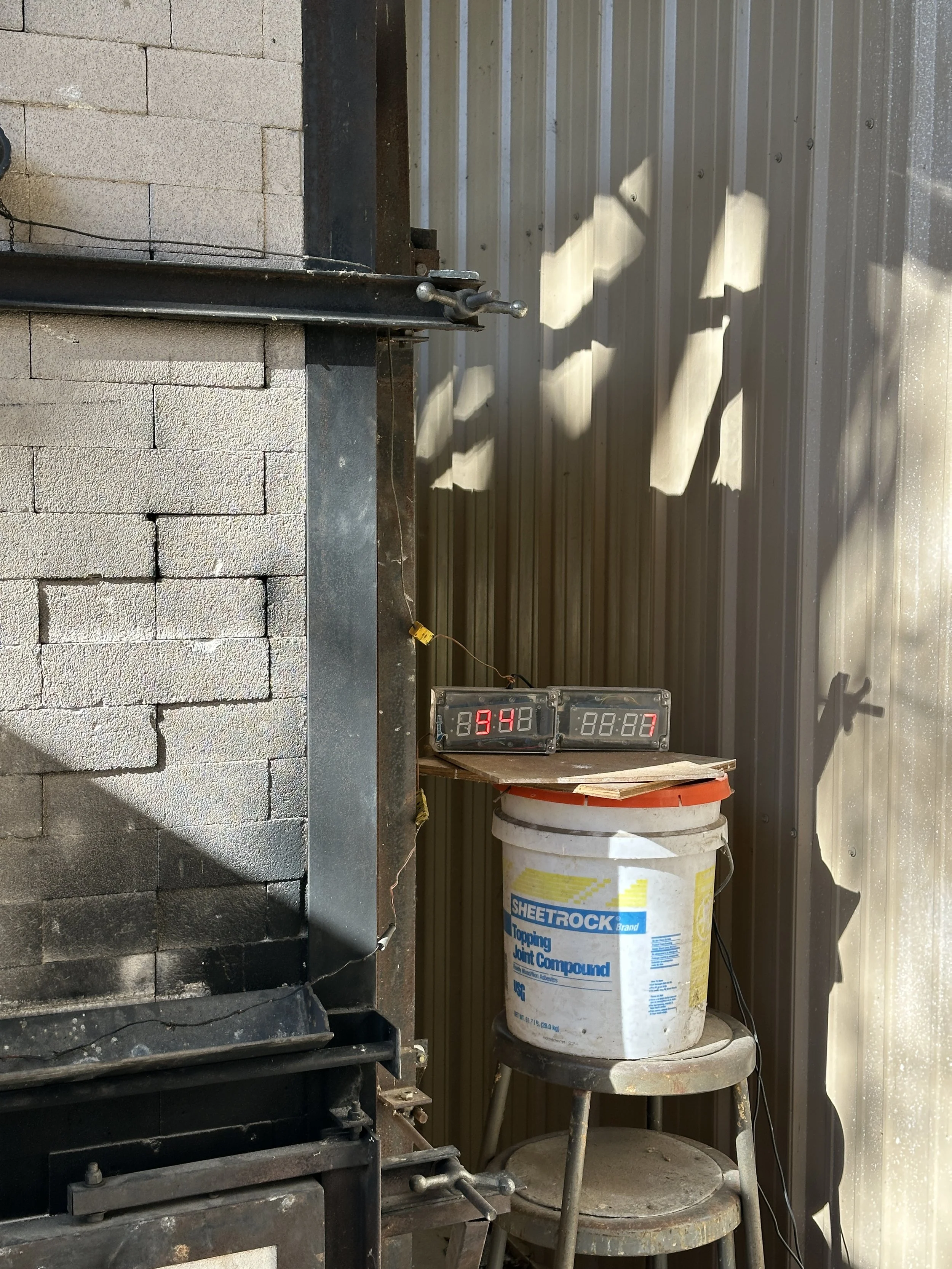

Without tracking data so closely, it's easier to find flow state. This was my fourth wood firing, the first time I've been left alone with the kiln, and the first time I have found this flow.

Toss/ Stoke, Wait.

Rake, Pause— and Watch.

Watch for the flame. It's long, searching for oxygen.

Toss/ Stoke, Wait.

While you wait, the fire breaks down the wood, using it as fuel.

As the wood burns, it creates more heat.

Rake— the embers, push them closer to the kiln chamber.

Pause— and watch. The flame flickers as the wood breaks down. There's more oxygen in the kiln now.

You pay attention. How many pieces of wood? What kind? How thick? How dry? How far back?

And then you find a rhythm. You relax a little.

My flower tumbers and a huge collection of test tiles, waiting to go in the kiln.

Dan Barnett is mixing another batch of wadding.

Cone packs are prepped and ready!

Bev <3

A tightly packed kiln slows the velocity— the pots act like stones in the river, slowing the stream— helping to coat the pots in sodium carbonate and wood ash.

Wadding pottery is required when firing pots in an atmospheric kiln, where the ash inside the kiln creates a glassy coating. Wadding is a clay like material made with a high alumina content which do not absorb silica.

Shells like wadding, act as a barrier between the pottery and the kiln shelf. The seashells are composed of calcium carbonate, that doesn't melt at high temperatures, but will easily dissolve in water.

Pushing the wood back and forth or raking creates has a few purposes. The flame magnifies, moving the wood helps get a better view of how full the boxes are. The wood that's burning hottest ends at the back of the box, where the chamber of the kiln is. When pushing the wood back and forth, the embers fall off and into the space below. Creating an even bed of ashes helps keep the boxes hot and prevents the space below would fill up too quickly.

This wood was soaking in sodium carbonate. We will stoke the kiln with it.